Welcome to the riveting journey of Webster & Horsfall, a company whose roots stretch back to the very fabric of the Industrial Revolution. In this series of articles, we unveil the rich history, connections with influential figures, and the pioneering spirit that has defined Webster & Horsfall through the ages. Join us as we explore the company’s unwavering commitment to innovation and its triumphs in undertaking monumental tasks.

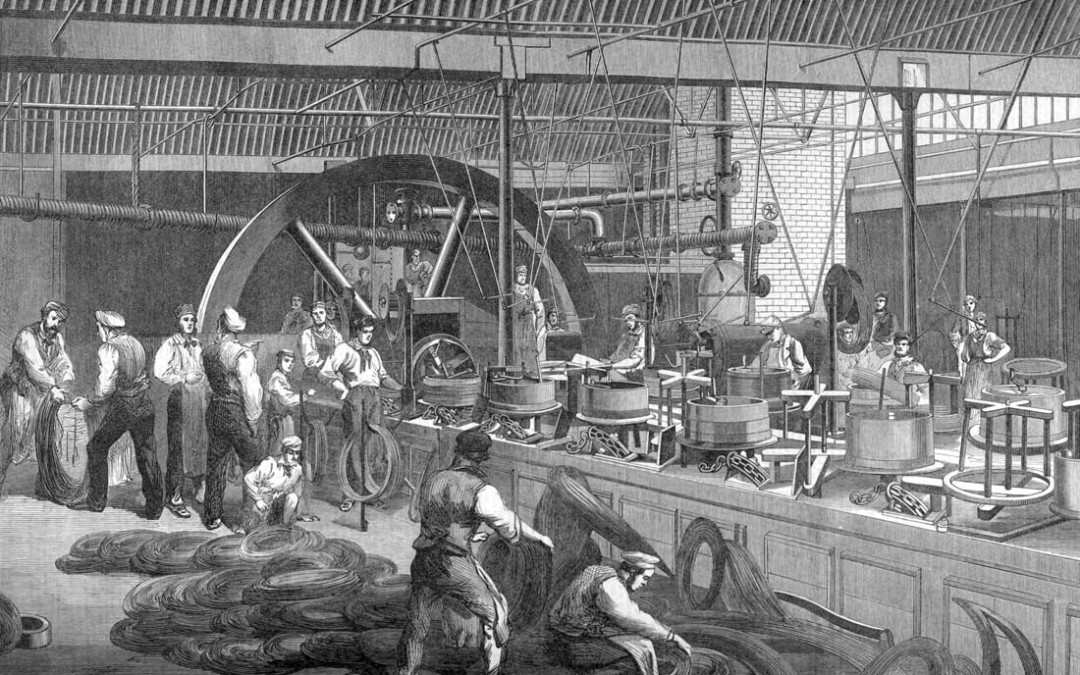

Wire Making

1855 – A Pivotal Year for Webster & Horsfall: The year 1855 marked the commencement of the formidable partnership between Webster and Horsfall, setting the stage for a transformative era in wire making. A significant challenge faced during this time was the maintenance of material quality, identified as a key obstacle in creating durable and robust wire.

Innovations and Leadership in Steel Production (1816-1825): Taking a leap back in time, since 1816, Webster & Horsfall had been at the forefront of experimentation with steel additives. In 1825, a groundbreaking achievement came to light – the production of high manganese steel wire. This innovation catapulted Webster & Horsfall ahead of international competition, securing their position for years to come.

Revolutionising Wire Strength (1860): The demand for high-grade steel surged in 1860 with the advent of oceanographic telegraphy. Webster & Horsfall rose to the challenge, particularly during the laying of the trans-Atlantic cable. The 1865 cable, which broke mid-Atlantic, was not lost but dredged up and spliced with the 1866 cable, leading to the remarkable feat of having two working cables from the start. This fascinating angle underscores the company’s ingenuity and resilience. The Atlantic Telegraph Company found itself with two working cables from the start! Interestingly, the 1866 cable worked for about 10 years before failing, however the 1865 cable lasted until 1931.

World Wars and Diversification:

During the two World Wars, Webster & Horsfall played a crucial role in supporting the war effort. In World War I, the company’s wire found application in manufacturing fuse springs for artillery shells, lining gun barrels, and supplying cords and ropes for Royal Naval ships. Similarly, in World War II, Webster & Horsfall’s contributions included manufacturing valve springs for Spitfires and other military machinery.

Webster & Horsfall’s journey through the archives of wire making is a testament to their unwavering commitment to quality, innovation, and meeting the demands of their time. As we delve deeper into their fascinating history, we’ll uncover more chapters of resilience, triumph, and a legacy that continues to shape the steel and wire manufacturing landscape.

“For over 120 years, we have been at the forefront of steel industry innovation. Today, our dedication lies in spearheading the path to a sustainable future for steel and steel manufacturing. Together, we forge a greener and more sustainable tomorrow.”